Mastering Ground Glass Joints: The Key to Safe and Efficient Laboratory Work

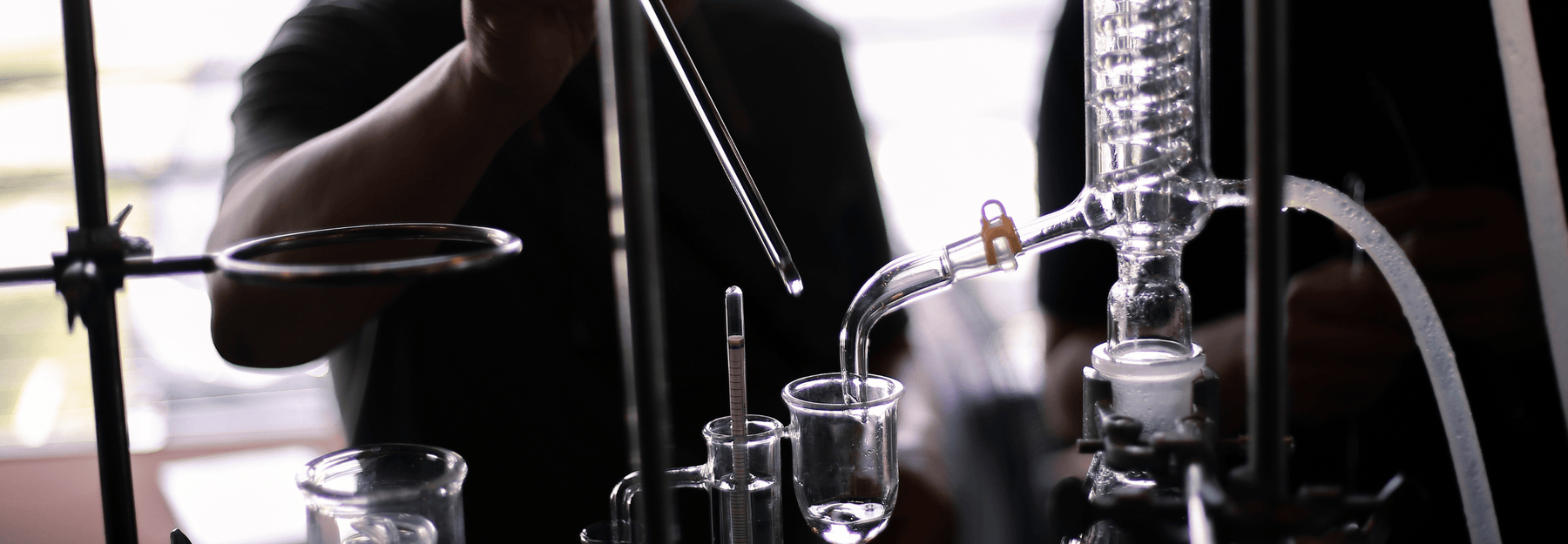

Glassware is the backbone of any laboratory experiment. And when it comes to precision and safety in organic chemistry, distillation, or extraction, ground glass joints are the unsung heroes of modern science. Gone are the days of messy rubber tubing and custom-made connections. Today, interchangeable jointed glassware has revolutionized lab work, making it safer, cleaner, and far more efficient.

But not all joints are created equal. Let’s explore the world of jointed glassware, its types, and the best practices to maximize safety and performance in your lab.

Why Jointed Glassware Matters

Did you know that improperly sealed joints can result in dangerous leaks or costly loss of valuable substances? Jointed glassware eliminates this risk. By connecting glassware components with precision, these joints ensure airtight, leak-proof setups that are essential for complex experiments.

With a wide variety of joint types, selecting the right one is crucial. Here’s a breakdown:

The Types of Ground Glass Joints

1. Conical Joints

The most common and versatile joint, conical joints are characterized by a tapered cone and socket design. Their rounded rim profile minimizes chipping and provides added durability. Perfect for distillation or reflux setups, these are the workhorses of laboratory glassware.

2. Spherical Joints

Need flexibility? Spherical joints allow for angular adjustments, ideal for applications like rotary condensers. As receiving flasks fill and get heavier, the flexibility of a spherical joint reduces strain, preventing cracks and breakages.

3. Flange Joints

Used for straight-line connections, flange joints are the go-to for large reaction vessels or pipeline assemblies. Their wide openings offer easy access for cleaning or adding reagents—an invaluable feature in industrial and academic labs alike.

4. Screw Thread Joints

Adjustable and robust, screw thread joints excel in dynamic setups. Whether you need to modify the length of an assembly or secure glassware in hard-to-reach spaces, these joints provide unparalleled flexibility.

Keck Clips: A Game-Changer in Safety

No discussion on jointed glassware is complete without mentioning Keck clips. These simple but essential tools securely hold joints together, preventing accidental slips or spills.

For high-temperature applications, stainless steel Keck clips are a must. They endure extreme heat where plastic clips might fail. To use them, simply snap the clip over the joint. Removal is just as easy, making them a user-friendly addition to any lab setup.

Tips for Safe Operation of Jointed Glassware

To get the most out of your laboratory glassware, safety is paramount. Here’s a quick guide:

- Inspect Before Use: Scratches or cracks weaken glassware and may lead to breakage under stress.

- Use Heat-Resistant Clips: When heating glassware, always use stainless steel Keck clips for secure connections.

- Avoid Thermal Shock: Heat and cool glassware gradually. Sudden temperature changes can cause glass to shatter.

- Clean Thoroughly: Wash all glassware before first use to avoid contamination from packaging residues.

- Handle With Care: Never force a connection. Misalignment can lead to cracks or stress fractures.

Advanced Best Practices

- Seal It Right: Silicone grease can help seal joints, but PTFE joint sleeves are a cleaner, non-contaminating alternative.

- Mind the Temperature: While borosilicate glass can handle up to 500°C for short periods, always check the temperature limits of attachments like stoppers or tubing.

- Use Diffused Heat: When using a Bunsen burner, employ a wire gauze to diffuse the flame and prevent hot spots.

- Volumetric Precision: Avoid applying direct heat to volumetric glassware—it compromises accuracy.

Why It All Matters

Jointed glassware isn’t just about making life in the lab easier; it’s about ensuring experiments run smoothly, safely, and without costly interruptions. From conical joints to Keck clips, each piece plays a vital role in your scientific journey.

By understanding your equipment and following these actionable tips, you can transform your lab work—boosting both efficiency and safety.

So the next time you set up a distillation or extraction, remember: the right joint makes all the difference.